2 Bolt Main VS 4 Bolt Main (Difference Guide) of 2024

When it comes to engine performance, every detail matters. One critical element often debated among car enthusiasts and mechanics is the choice between 2 Bolt Main VS 4 Bolt Main configurations.

Understanding the differences between these two can significantly impact your engine’s performance and durability. So, let’s dive into what sets them apart and which might be the better choice for your needs.

What is a Main Bearing?

Before we compare, let’s clarify what a main bearing is. Simply put, the main bearings are crucial components that support the crankshaft and allow it to rotate smoothly. They absorb the engine’s stresses and keep the crankshaft aligned. There are a few types of main bearings, but the most common ones are the 2 bolt and 4 bolt configurations.

The 2 Bolt Main Configuration

A 2 bolt main configuration features two bolts per main bearing cap. This setup is generally found in more standard or less aggressive engines.

- Description: The 2 bolt main setup is straightforward, with two bolts securing each bearing cap to the engine block.

- Common Applications: This configuration is commonly used in standard passenger vehicles and many early model engines.

- Advantages: It’s typically less expensive to produce and install. For everyday driving, it offers sufficient strength and reliability.

- Disadvantages: The main downside is reduced strength compared to the 4 bolt main. It’s less suitable for high-stress applications, such as racing or heavy-duty use.

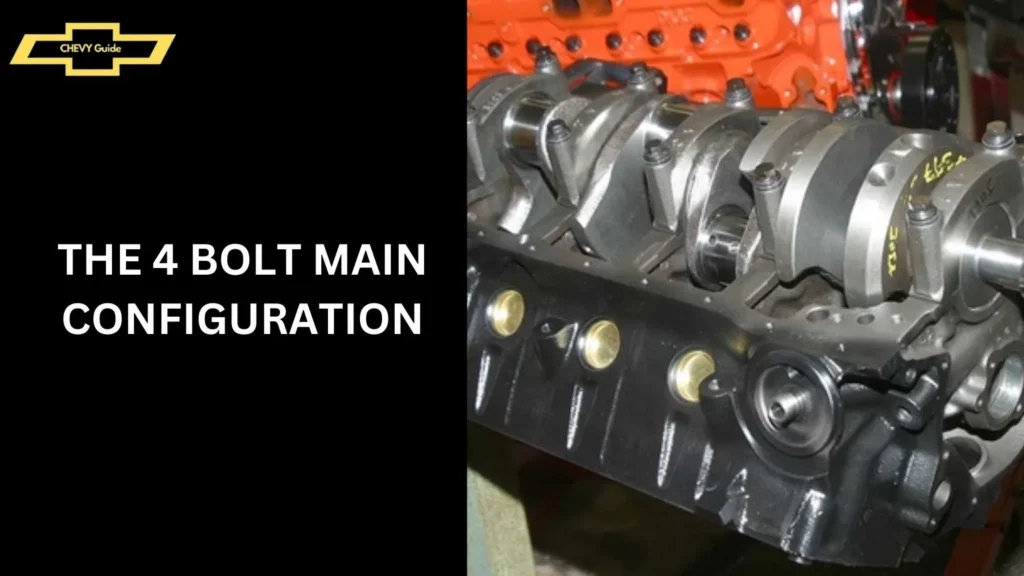

The 4 Bolt Main Configuration

The 4 bolt main configuration enhances durability by using four bolts per main bearing cap, offering increased support.

- Description: This setup includes two additional bolts compared to the 2 bolt main, providing extra strength and stability.

- Common Applications: You’ll find 4 bolt mains in high-performance engines, including those in racing cars and heavy-duty trucks.

- Advantages: The added bolts significantly improve the strength and durability of the engine. This setup is ideal for high-torque applications and extended engine life.

- Disadvantages: It’s more expensive to produce and install, and may be overkill for standard driving needs.

Comparing 2 Bolt Main VS 4 Bolt Main

When comparing these configurations, strength and performance are key factors.

- Strength and Durability: The 4 bolt main is superior in strength, making it more suitable for high-performance engines that endure greater stresses.

- Performance Differences: Engines with 4 bolt mains can handle more power and torque, reducing the risk of bearing cap failure.

- Cost Implications: While 4 bolt mains are more costly initially, their increased durability can lead to lower long-term maintenance costs.

Performance Applications

For high-performance engines, the 4 bolt main is often the preferred choice. Its enhanced strength allows for higher RPMs and greater power outputs, making it suitable for racing or performance tuning. For example, many performance-oriented vehicles and race cars use 4 bolt mains to ensure reliability under extreme conditions.

Installation Considerations

Installing a 2 bolt main is generally more straightforward and less expensive. However, for a 4 bolt main, precise installation is crucial to avoid alignment issues and ensure optimal performance. Consider the added complexity and costs when opting for a 4 bolt main.

Maintenance and Longevity

When it comes to maintenance and longevity, both 2 bolt main and 4 bolt main configurations have specific requirements and performance expectations. Here’s a closer look at what you can expect from each:

2 Bolt Main Maintenance and Longevity

- Regular Maintenance: For a 2 bolt main engine, regular maintenance is crucial to ensure its longevity. This includes routine oil changes, timely replacement of worn-out parts, and periodic inspections to detect any early signs of wear and tear.

- Suitable Applications: Under normal driving conditions and moderate stress levels, a 2 bolt main configuration can last a long time. It’s well-suited for everyday vehicles that don’t endure high-performance demands.

- Potential Weak Points: The main area of concern with 2 bolt mains is the possibility of bearing cap movement under high stress, which can lead to crankshaft misalignment and engine damage. Regular checks can help mitigate this risk.

4 Bolt Main Maintenance and Longevity

- Enhanced Durability: The 4 bolt main configuration is designed to handle higher stress and torque, which translates to increased durability. This setup provides more support to the crankshaft, reducing the risk of movement and wear.

- Maintenance Needs: While 4 bolt mains are more robust, they still require regular maintenance to perform at their best. This includes the same routine tasks as with 2 bolt mains but with the added assurance that the engine can handle more stress.

- Longevity in High-Stress Situations: Engines with 4 bolt mains are better equipped to handle high-stress situations, such as racing or heavy-duty use. This means they are less likely to experience failure under extreme conditions, leading to a longer engine life.

- Reliability: Due to the additional support provided by the extra bolts, 4 bolt main engines tend to be more reliable in the long run. This reliability makes them a preferred choice for performance enthusiasts and professionals who push their engines to the limit.

Cost Comparison

- Initial Cost: The 4 bolt main is more expensive due to its complex design and higher manufacturing costs.

- Long-Term Costs: The 4 bolt main can save money in the long run by reducing the frequency of repairs and replacements due to its increased durability.

Choosing the Right Configuration for Your Needs

When deciding between a 2 bolt and a 4 bolt main, consider your driving style and engine needs. If you’re building a high-performance engine or frequently push your vehicle to its limits, the 4 bolt main is likely the better choice. For everyday driving, a 2 bolt main provides adequate performance and is more cost-effective.

People also ask

Is a 2 bolt main better than a 4 bolt main?

A 4 bolt main is generally better than a 2 bolt main for high-performance and heavy-duty applications due to its increased strength and durability. It offers greater support to the crankshaft, making it more suitable for engines that experience high stress and torque. However, a 2 bolt main is typically sufficient for everyday driving and is more cost-effective, making it a good choice for standard passenger vehicles.

What is the purpose of a 4 bolt main?

The purpose of a 4 bolt main is to provide increased strength and stability to the engine’s crankshaft by using four bolts per main bearing cap. This configuration enhances the engine’s durability, especially under high stress and torque conditions, making it ideal for high-performance and heavy-duty applications.

How much horsepower can a 2 bolt 454 handle?

A 2 bolt 454 engine can typically handle around 500 to 550 horsepower with proper tuning and maintenance. For higher horsepower applications, reinforcing the engine or upgrading to a 4 bolt main is recommended for added strength and reliability.

Is a Pontiac 400 a 4 bolt main?

Most Pontiac 400 engines come with a 2 bolt main configuration. However, some high-performance versions, such as the Ram Air IV, were equipped with a 4 bolt main for added strength and durability.

Conclusion

In summary, both 2 bolt and 4 bolt mains have their advantages and are suited for different applications. Understanding your specific needs and engine requirements will guide you in making the best choice. While the 4 bolt main offers enhanced strength and durability, it comes with a higher price tag. The 2 bolt main, on the other hand, is more economical and sufficient for standard driving needs.

My name is James Henry, and I’m thrilled to share my passion for Chevy vehicles with you. With over a decade of hands-on experience in car repair and a deep love for everything Chevy, I’ve dedicated this site to helping fellow enthusiasts and owners navigate the world of Chevrolet.